DP5605 OLP – 3/8 in. x 50 ft. Ultimate Duty Dual Pedestal Hose Reel

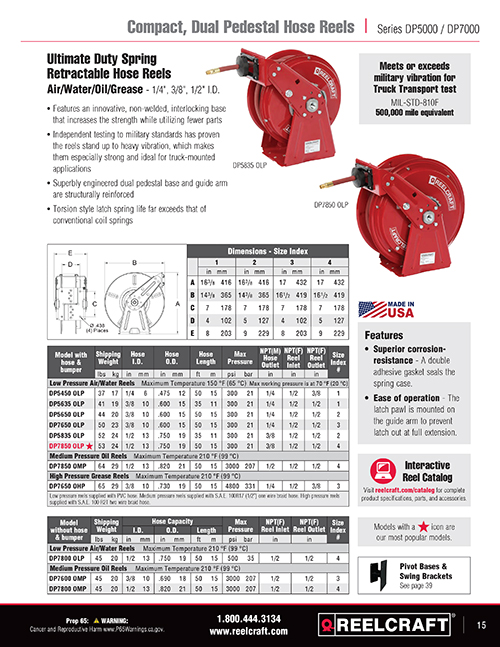

The Reelcraft Series DP5000 compact, dual pedestal hose reel features an innovative, non-welded, interlocking base. Independent testing to military standards has proven the reel stand up to heavy vibration, which makes them especially strong and ideal for truck-mounted applications. The all-steel construction and a baked-on powder coat finish combine to produce a rugged corrosion-resistant product suitable for a wide variety of heavy-duty applications.

- Reinforced steel – Steel guide arm and dual pedestal base are stamped with ribs and gussets to ensure maximum strength and lightest possible weight. The interlocking base eliminated the need for welds increasing the strength while utilizing fewer parts.

- Superior latch spring design – The life of the torsion style latch spring far exceeds that of conventional coil springs.

- Long life drive spring – Declutching arbor eliminates reverse spring winding, and torsion latch spring is virtually unbreakable. High-quality spring steel is used and conditioned to ensure there are no imperfections offering maximum service life.

- A double adhesive gasket seals the spring case.

- The latch pawl is mounted on the guide arm to prevent latch out at full extension.

- Made in the USA

10 business day estimated lead time. For large quantities, please consult Reelcraft Customer Service.

10 business day estimated lead time. For large quantities, please consult Reelcraft Customer Service.

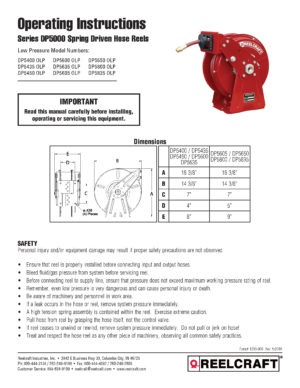

Reel Specifications and Dimensions

Additional information

| Weight | 38 lbs |

|---|---|

| Series | |

| Hose I.D. | |

| Hose O.D. | |

| Hose Length | |

| Pressure | |

| Inlet | |

| Reel Outlet | |

| Hose Included | |

| Max Temperature | |

| UPC | 699567007357 |

| Carton Dimensions | 18.5" x 10" x 19.5" |

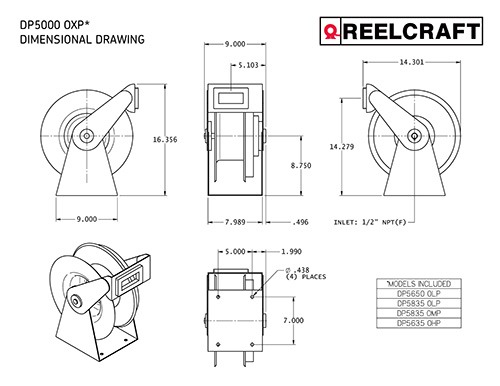

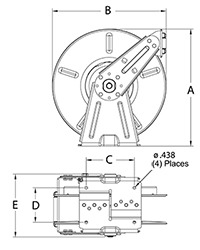

| A | 16.375" |

| B | 14.375" |

| C | 7" |

| D | 5" |

| E | 9" |

Fluid Path Materials

| Internal Fluid Path | Steel |

| Swivel Assembly | Steel |

| Swivel Seal | Aflas |

Parts

Bumper Stop

Accessories

Video

FAQs

Increase or decrease the spring tension on your Reelcraft hose or cord reel to improve retraction performance.

When to Adjust Spring Tension

Adjust spring tension if:

- The reel won’t fully retract the hose or cord.

- It pulls back too slowly or with too little force.

- You’ve changed the hose or cord length or weight.

How to Increase Spring Tension

Increasing spring tension helps the reel pull the hose or cord in more firmly. Adding wraps of hose or cord will increase the spring tension. You can also watch our Reelcraft how-to video for step-by-step visual instructions on adjusting the spring tension for single pedestal reels.

Steps:

- Pull out 10 ft (3 m) of hose or cord.

- Feed the hose/cord back up through the roller bracket assembly until you can form a loop over the spool.

- Add 1-3 wraps around the reel spool until desired tension is achieved.

- Check tension and repeat until the desired retraction strength.

⚠️ Tip: Do not exceed the reel’s spring capacity — too much tension can damage the reel.

Special Note for Dual Pedestal Reels

You will need to remove the bumper and control handle then feed the end of the hose through the roller bracket assembly to add or remove wraps of hose from the reel. You can also watch our Reelcraft how-to video for step-by-step visual instructions on adjusting the spring tension for single pedestal reels.

How to Decrease Spring Tension

Reducing spring tension can make it easier to pull out longer hoses or cords.

Steps:

- Remove wraps from the reel spool, one at a time.

- After each wrap is removed, test retraction to make sure the tension is right.

Quick Tips

- Always test after small adjustments — one wrap can make a big difference.

- If your reel still doesn’t retract properly after tension adjustment, check the guide arm position, U-bolt placement, or contact Reelcraft support.

- Watch our Reelcraft how-to videos for additional help on maintaining and servicing your reel.

Can my spring driven reel be made constant tension?

Most Reelcraft spring retractable reels can be made constant tension by removing the latching system. There are some models that may not have this capability.

Please refer to our online tech bulletins for more information on converting your reel to constant tension.

How do I install a new drive spring and set pre-turns?

We have several different types of spring-driven reels. Each requires a slightly different set of instructions. For “How-To” instructions on replacing a drive spring, please have your reel model or drive spring number available and consult customer service for instructions.

For how many wraps of “pre-tension” to put on the reel, please reference the chart below.

| Spring Number | Wraps Required |

| S400030 | 18 |

| S404230 | 13 |

| S504240 | 19 |

| S505740 | 13 |

| S503755 | 21 |

| S600050 | 21 |

| S600620 | 19 |

| S504230 | 17 |

| 602718-80 | 33 |

| 602720-100 | 27 |

| 602720-70 | 25 |

| 602721-80 | 21 |

| 602733 | 33 |

How many GPMs will I get from my hose?

GPM = gallons per minute is a function of hose diameter, hose length, supply pressure and fluid going through the hose/reel. The most common fluids, air and water, can be seen in charted data. For hydraulic oils, it is necessary to know the operating temperature, pressure and fluid viscosity.

Why will my hose reel or cord reel not retract?

Insufficient Spring Tension

Adjust the spring tension by adding wraps of hose. Pull out approximately 10 feet of hose. Hand feed the hose back up through roller bracket assembly until the loop is large enough to slip over sheave. Add two or three wraps until desired tension is achieved. Do not exceed spring capacity. Watch our “How to Adjust Spring Tension” videos on our Technical Videos page for more help.

Hose / cord reel mounted on ceiling above 16 feet

Control handle weight must also be considered. Contact Reelcraft for further information.

Latch mechanism engaged with drive spring coiled to solid height

U-bolt hose clamps on sheave assembly not positioned correctly.

Hose / cord fully extended will not retract

Latch mechanism engaged with drive spring is coiled to solid height. U-bolt hose clamps on sheave assembly are not positioned correctly.

Product supply to reel, rigid, plumbed in

If a flexible connecting hose is not used between hose reel inlet and hard plumbing, you stand the chance of causing excessive bind to main shaft and hub bearings causing reel not to retract. This will also void the warranty.

Reel mounted on uneven surface

Bolting the reel down to an uneven surface will distort the side frames causing a bind on main support shafts and restricting smooth retraction of the hose.

Wrong guide arm position

If the guide arm is in side wind position for ceiling mounted reels, the hose / cord is bending at a 90° angle over roller bracket assembly. This can cause excessive loss of spring tension. Adjust the guide arm to coincide with how the hose / cord reel is actually mounted. U-bolt clamps may also need to be adjusted.

Broken main spring, broken spring arbor, corrosion on shaft and hub

Replace broken part with new. For corrosion: disassemble reel and remove corrosion, lubricate and reassemble.

Why is fluid or air leaking from my swivel?

O-ring worn out or wrong O-ring for material being handled

Replace O-rings with O-ring kit or replace with correct rings for material being handled.

Swivel may be loose or not enough pipe thread sealant on shaft threads

Remove swivel and check threads ensuring they are in good condition. Reapply thread sealant and install swivel onto reel ensuring good thread engagement.

Why will my reel not latch?

If your reel will not latch, it could mean the latch spring is broken or the latch pawl or latch plate is bent. The broken or bent part(s) will need to be replaced.

Refer to our Service Manuals page for assistance finding your parts.