L 70100 123 X – 12/3 100 ft. Heavy Duty Flying Lead Power Cord Reel

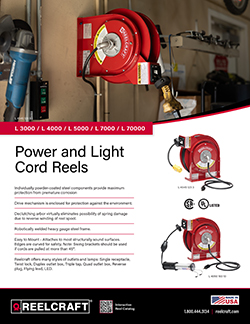

Reelcraft Series L 70000 cord reels incorporate a heavy-duty base design, all-steel construction and a baked-on powder coat finish to produce a rugged, corrosion-resistant product. A newly redesigned latching mechanism provides a longer service life for the latch components. The containerized drive spring offers safer and easier handling during maintenance. Two sealed ball bearings produce a smoother spool rotation and easier operation. The guide arm adjusts to seven positions for various mounting locations and applications. For indoor, non-weather tight applications only. *UL/CSA approved*

- 100 ft. 12/3 SEOOW cord with flying lead included

- Redesigned latching mechanism provides longer service life for the latch components

- Guide rollers – The one-piece design and stainless steel pins offer greater strength and easier serviceability

- Containerized drive spring offers easier handling during maintenance

- All-steel electrical enclosure – Offers a stronger, more durable protective cover of electrical components

- Base plate and upright are constructed from 7 gauge steel; the guide arm is 11 gauge and the spool is 16 gauge steel

- Guide arm adjusts to seven positions

- Ease of operation – The high-quality, die-cast aluminum hub, and two sealed ball bearings produce a smoother spool rotation and easier operation

- Made in the USA

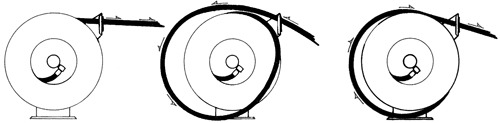

*Reel is shipped in the top wind position. The reel image is shown in the side wind position.

10 day estimated lead time. For large quantities, please consult Reelcraft Customer Service.

10 day estimated lead time. For large quantities, please consult Reelcraft Customer Service.

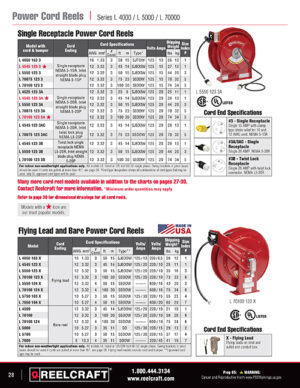

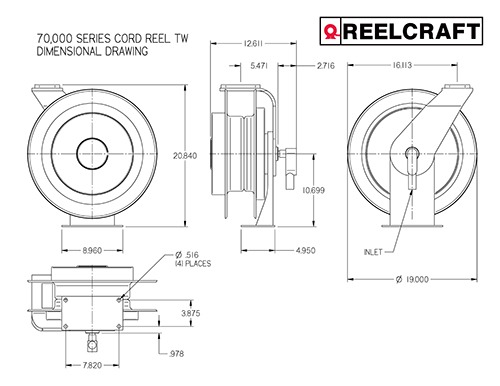

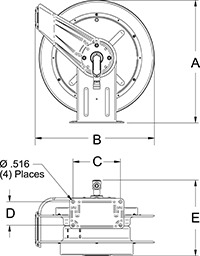

Reel Specifications and Dimensions

Additional information

| Weight | 73 lbs |

|---|---|

| Series | |

| Cord Ending | |

| AWG | |

| Cord/Cable Length | |

| Volts | |

| Amps | |

| Conductors | |

| Cord/Cable Included | |

| Type | |

| UPC | 699567018247 |

| Carton Dimensions | 21.25" x 13.5" x 22.25" |

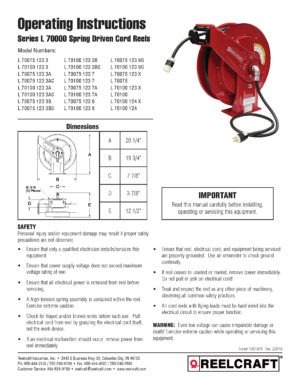

| A | 20.25" |

| B | 19.75" |

| C | 7.8125" |

| D | 3.875" |

| E | 11.75" |

Parts

Bumper Stop

Accessories

Pivot Base

Swing Bracket

Video

FAQs

Increase or decrease the spring tension on your Reelcraft hose or cord reel to improve retraction performance.

When to Adjust Spring Tension

Adjust spring tension if:

- The reel won’t fully retract the hose or cord.

- It pulls back too slowly or with too little force.

- You’ve changed the hose or cord length or weight.

How to Increase Spring Tension

Increasing spring tension helps the reel pull the hose or cord in more firmly. Adding wraps of hose or cord will increase the spring tension. You can also watch our Reelcraft how-to video for step-by-step visual instructions on adjusting the spring tension for single pedestal reels.

Steps:

- Pull out 10 ft (3 m) of hose or cord.

- Feed the hose/cord back up through the roller bracket assembly until you can form a loop over the spool.

- Add 1-3 wraps around the reel spool until desired tension is achieved.

- Check tension and repeat until the desired retraction strength.

⚠️ Tip: Do not exceed the reel’s spring capacity — too much tension can damage the reel.

Special Note for Dual Pedestal Reels

You will need to remove the bumper and control handle then feed the end of the hose through the roller bracket assembly to add or remove wraps of hose from the reel. You can also watch our Reelcraft how-to video for step-by-step visual instructions on adjusting the spring tension for single pedestal reels.

How to Decrease Spring Tension

Reducing spring tension can make it easier to pull out longer hoses or cords.

Steps:

- Remove wraps from the reel spool, one at a time.

- After each wrap is removed, test retraction to make sure the tension is right.

Quick Tips

- Always test after small adjustments — one wrap can make a big difference.

- If your reel still doesn’t retract properly after tension adjustment, check the guide arm position, U-bolt placement, or contact Reelcraft support.

- Watch our Reelcraft how-to videos for additional help on maintaining and servicing your reel.

Can my spring driven reel be made constant tension?

Most Reelcraft spring retractable reels can be made constant tension by removing the latching system. There are some models that may not have this capability.

Please refer to our online tech bulletins for more information on converting your reel to constant tension.

How do I install a new drive spring and set pre-turns?

We have several different types of spring-driven reels. Each requires a slightly different set of instructions. For “How-To” instructions on replacing a drive spring, please have your reel model or drive spring number available and consult customer service for instructions.

For how many wraps of “pre-tension” to put on the reel, please reference the chart below.

| Spring Number | Wraps Required |

| S400030 | 18 |

| S404230 | 13 |

| S504240 | 19 |

| S505740 | 13 |

| S503755 | 21 |

| S600050 | 21 |

| S600620 | 19 |

| S504230 | 17 |

| 602718-80 | 33 |

| 602720-100 | 27 |

| 602720-70 | 25 |

| 602721-80 | 21 |

| 602733 | 33 |

Why will my hose reel or cord reel not retract?

Insufficient Spring Tension

Adjust the spring tension by adding wraps of hose. Pull out approximately 10 feet of hose. Hand feed the hose back up through roller bracket assembly until the loop is large enough to slip over sheave. Add two or three wraps until desired tension is achieved. Do not exceed spring capacity. Watch our “How to Adjust Spring Tension” videos on our Technical Videos page for more help.

Hose / cord reel mounted on ceiling above 16 feet

Control handle weight must also be considered. Contact Reelcraft for further information.

Latch mechanism engaged with drive spring coiled to solid height

U-bolt hose clamps on sheave assembly not positioned correctly.

Hose / cord fully extended will not retract

Latch mechanism engaged with drive spring is coiled to solid height. U-bolt hose clamps on sheave assembly are not positioned correctly.

Product supply to reel, rigid, plumbed in

If a flexible connecting hose is not used between hose reel inlet and hard plumbing, you stand the chance of causing excessive bind to main shaft and hub bearings causing reel not to retract. This will also void the warranty.

Reel mounted on uneven surface

Bolting the reel down to an uneven surface will distort the side frames causing a bind on main support shafts and restricting smooth retraction of the hose.

Wrong guide arm position

If the guide arm is in side wind position for ceiling mounted reels, the hose / cord is bending at a 90° angle over roller bracket assembly. This can cause excessive loss of spring tension. Adjust the guide arm to coincide with how the hose / cord reel is actually mounted. U-bolt clamps may also need to be adjusted.

Broken main spring, broken spring arbor, corrosion on shaft and hub

Replace broken part with new. For corrosion: disassemble reel and remove corrosion, lubricate and reassemble.

Why will my reel not latch?

If your reel will not latch, it could mean the latch spring is broken or the latch pawl or latch plate is bent. The broken or bent part(s) will need to be replaced.

Refer to our Service Manuals page for assistance finding your parts.

If you are in the market to buy a cord reel, you may have some questions. Whether you want something to be permanently mounted on your garage wall or you need something that can be mounted on a cart so it’s portable, there are some things that you’ll want to consider.

Metal or Plastic

One of the first things you might consider when looking at purchasing a reel is metal or plastic. Do you want a metal cord reel that’s durable and strong? Or do you want a reel that’s maybe lighter in weight? If so, you may consider a reel made from plastic. Depending on your application, a metal or plastic reel could benefit you differently. Especially in terms of weight. If you are mounting it to something portable, you may not want it to be heavy. But if your reel is going to be completely stationary or outside, you may want to consider a more heavy-duty material like metal.

Mobile or Permanently Mounted

Also, it is important to know if you want your reel to be mobile or permanently mounted. If you are going to permanently mount your reel then you’ll want the traditional inlet and outlet cord. For someone who is looking for a mobile reel, there are reels that have the inlet and outlet reversed. This means when you mount your reel on a cart to make it mobile, the inlet cord is the long length of cord that is wrapped up on the spool, and the outlet cord is the short stationary one. This allows you to plug in your reel and move your cart around by having the cord unwind off your reel and using the outlet on the cart.

UL-Listed?

Another important thing to consider is whether the reel you are looking to purchase is UL-listed or not. Being UL-listed is important if you want the reassurance of the safety of your reel. UL-listed means that the reel has been tested by UL, an independent agency to be sure that the reel performs under the rated load. Benefits of this include not having to completely unwind your reel to make sure it does not overheat. To see if the reel you are considering buying is UL-listed, look for the UL-listed logo on the tag or packaging.

Amperage and Voltage

Amperage and voltage are other important things to consider. Depending on your application you might require a higher rating of volts or amps, or you may not need as much if your application is less demanding or if the reel is occasionally used.

Other Features

After all of that is considered, you can start looking into more specifications such as the number of outlets on the cord endings, if you want a light on your reel, and the length of the cord. All these attributes can be chosen when ordering your reel. Be sure to consider your application, how often you are going to be using your reel, and the environment your reel is going to be in.

Purchasing a reel might be overwhelming if you are not sure what to look for. By considering what you do know about your application, environment, and preferences, it can all be a piece of cake.